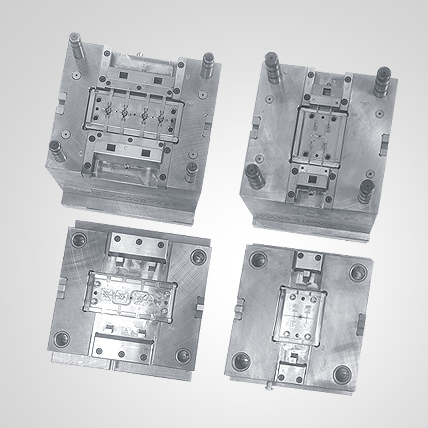

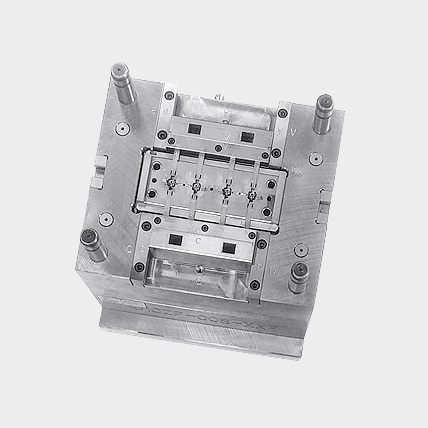

The heart of injection molding system is the mold. Excellent design and well-made molds are the key for making high-quality molded parts. Since the establishment of Jin Shuh Enterprise, the driving force for the company's success has been the mold fabrication capabilities. Jin Shuh Enterprise has mold tooling shop in-house with excellent mold design and fabrication capabilities. We use 3D software for mold design and 3D simulation, and utilize 3D mold flow simulation software for design verification, optimization, and manufacturability evaluation.

The heart of injection molding system is the mold. Excellent design and well-made molds are the key for making high-quality molded parts. Since the establishment of Jin Shuh Enterprise, the driving force for the company's success has been the mold fabrication capabilities. Jin Shuh Enterprise has mold tooling shop in-house with excellent mold design and fabrication capabilities. We use 3D software for mold design and 3D simulation, and utilize 3D mold flow simulation software for design verification, optimization, and manufacturability evaluation.

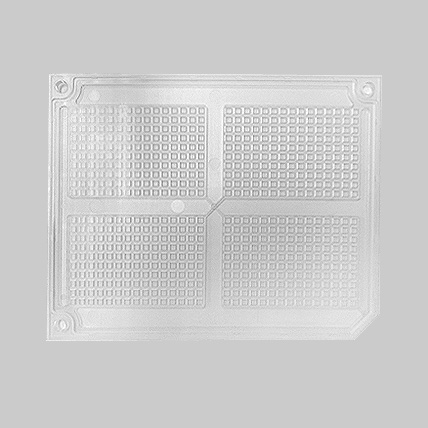

Utilizing professional knowledge, advanced technology and latest software, combining with years of experience in design, plastic injection mold development, and injection molding technology, the molds built by Jin Shuh Enterprise has advantages in high precision, high efficiency, high reliability, and long service life. For the high-volume production mold (SPI 101) fabricated by Jin Shuh, we offer a warranty from a one million shots warranty, and up to10-Year Warranty or Product Life Warranty.

To perfect the design, we test, test, and test again. We use 3D mold flow analysis software to verify the design. Mold flow analysis software simulates the flow behavior of plastics, allowing us to accurately predict how molten plastic will flow through molds and identify potential issues that could lead to manufacturing defects. Potential problem spots can be identified in the early stages of product and mold design development. This information helps us to further optimize part and mold design before mold tooling is cut, avoiding costly product design changes and mold modification costs.

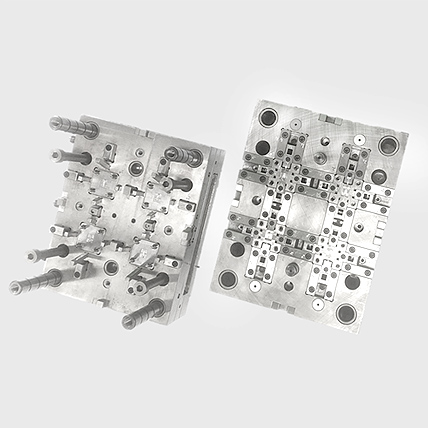

For the mold developed by Jin Shuh Enterprise, we adopt multi-insert design for the cavity and core of the mold to achieve more design flexibility and better mold exhaust design, and make mold maintenance more convenient. By means of mold spare parts and quick replacement of inserts, the high cost and production line downtime caused by the need to repair the entire mold can be avoided. The multi-insert design of the mold structure is also used in our quick-mold-change design and the mold insert exchangeable design. The quick-mold-change design allow Jin Shuh to be able to achieve faster mold change time at the production site, minimize production downtime, and greatly increase the productivity. For products with multiple specifications but low-volume in demand, the mold insert exchangeable design can be used to reduce expensive mold costs for our customers.

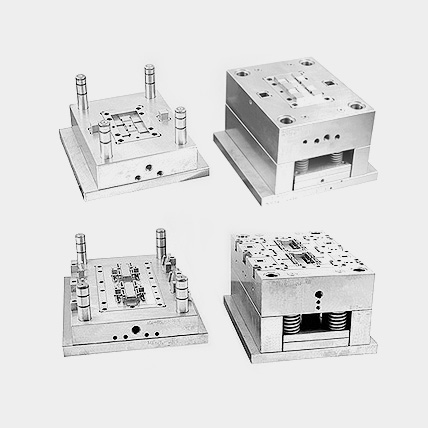

Jin Shuh Enterprise’s Mold design & tooling team has the ability to design and build various types of molds. Jin Shuh can build all type of mold required for your project, from prototype mold, high-volume mass production mold, traditional cold runner molds, hot runner molds, rotary 2Cmolding molds, over-molding mold, insert molding mold, and transfer molding mold, etc., Jin Shuh has years of experience, can produce the best quality molds to meet the various needs of customers for various products, and has the ability to become your one-stop mold tooling solution partner.

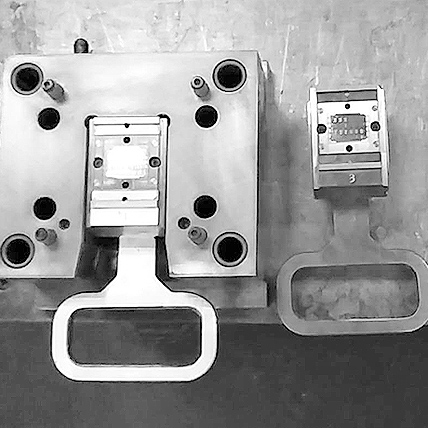

Jin Shuh Enterprise not only focuses on making high-precision molds, we also provide machining services for a wide variety of application. Jin Shuh Enterprise provides high-quality custom tooling parts and precision tools for many world-well-known companies, and can meet various specifications and standards required by customers. We have all kinds of precision machining equipment such as SODICK high-precision CNC discharge and wire cutting machines, which can provide you with high-quality and high-precision parts. From mold ejector pins, to detailed mold spare parts, to jigs, fixtures and custom tool gauges, we've got you covered.